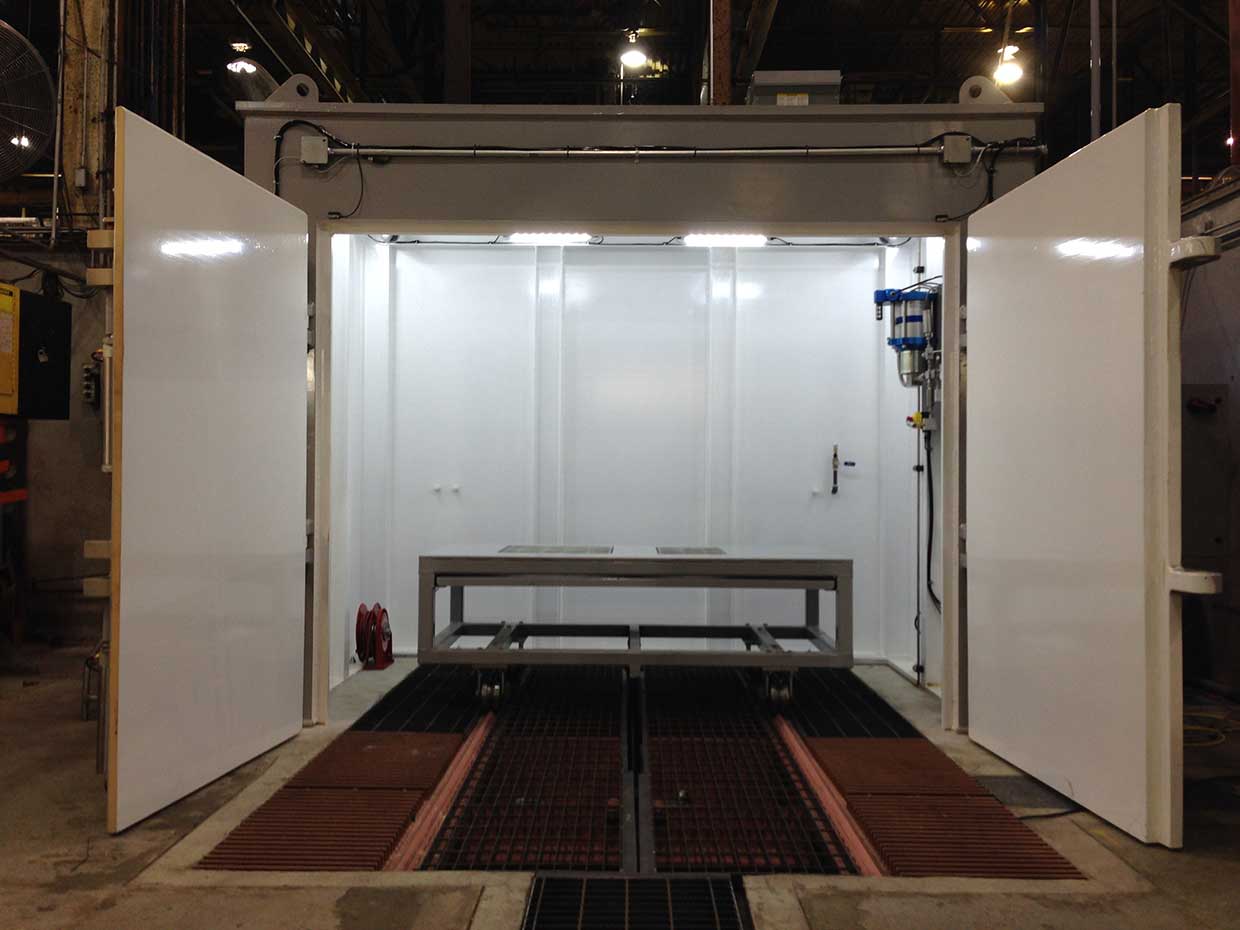

Why Are Xilix Hydrostatic Pressure Test Chambers Essential for High-Pressure Testing?

Industries that require extreme precision and safety in hydrostatic testing rely on advanced pressure chambers to ensure structural integrity, leak prevention, and compliance with safety regulations. The Xilix Pressure Test Chamber System is specifically designed to withstand high-pressure environments up to 100,000 PSI, delivering accurate test results while minimizing risk.

Xilix Systems is a leading engineering group specializing in the design and manufacturing of hydrostatic testing solutions. Our pressure test chambers provide unparalleled safety, automation, and precision measurement for critical applications across industries such as oil and gas, nuclear power, semiconductors, food and beverage, and medical devices.